1. Organic Contamination

2. Iron Contamination

3. Weld Spatter

4. Undercut

5. Tarnish

6. Scale Layers & Residual Slag

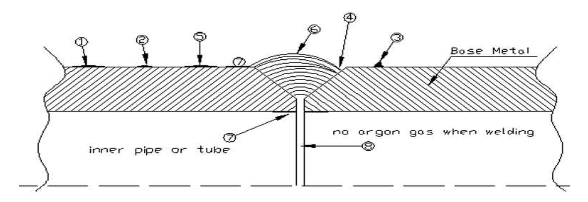

7. Oxidation Tints ( inner and outer pipe / tube on welding zone )

8. Leak of Penetration ( produced small gaps around circum of welding zone inside pipe / tube ).

Welding Quality of Hygienic and others Processing Line

| No | Level of Quality | Welding Method | Finishing | Deffect | Effect | Solution |

|---|---|---|---|---|---|---|

| 1 | Poor | GTAW single butt welding without Insert of argon gas. |

- no pickling. - no mechanical polesh. - no pickling and passivation inside pipe / tube. |

- scale layers. - oxidation tints. - tarnish. - iron & organic contamination. - gap around circum weld inside pipe / tube. |

- lower resistant to corrosion on welding zone inside & outside pipe. - bacterial zone or deposit zone inside pipe / tube. - leakage on process. - product. - Contamination. - high maintenance cost. - high production cost. |

- pickling with St.W.C outside. - mechanical polesh outside. - inside leak of penetration,repair welding line using insert gas argon and finally pickling & pasivation with S.S.C + P.L.S + water. |

| 2 | Fair |

- GTAW single butt welding with insert of nitrogen gas. - Full penetration inside pipe. |

- pickling or mechanical polesh on welding zone outside. |

- follow to pickling or mechanical polesh procedure all deffect outside pipe / tube will removed. - oxidation tints, scale layers, tarnish on welding zone inside pipe / tube. |

- high resistant to corrosion on welding zone outside pipe / tube. - no contamination and clean surface. - lower resistant to corrosion on welding zone inside pipe / tube. - product live time. - moderate maintenance cost & production cost. |

- pickling and passivation inside pipe or tube by circulation mix of : 2 part P.L.S + 2 parts S.S.C + 2 parts treated water. - For about 30 minutes holding time. |

| 3 | Good | - GTAW single butt welding with insert of argon gas. -Full penetration inside tube. | - pickling or mechanical polesh on welding zone outside. - tube inside buffing 300#. - pickling and passivation inside tube by circulation mix of : - 2 parts P.L.S + 1 part S.S.C + 3 parts treated water. - For about 30 minutes of holding time. | - no deffect - no deffect, no bacterial zone. | - clean surface - high corrosion resistant - both inside and outside tube. - no contamination. - no bacterial zone. - low maintenance cost. - product live time. - more productivity. | |

| 4 | Excellent | - Orbital welding with insert argon gas. Sanitary tube or electropolishing tube. | - polishing to 300#. - sanitary tube inside or electropolishing. - pickling & passivation inside tube by circulation 1 part P.L.S + 1 part treated water. - For about 30 minutes holding time. | - no deffect. - no bacterial zone. | - excellent surface. - no contamination. - good product live time. - more productivity. |